VOT3D

Ventilation Optimizing Technology based on 3D-scanning

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Background of the Project

The digitization and robotization of the mining industry are major trends as they provide significant advantages in terms of productivity and safety. Underground resource extraction relies heavily on effective mine ventilation to maintain optimal conditions in workplaces. Despite annual costs exceeding millions per plant, the role of ventilation in enhancing work efficiency and safety is invaluable. Current practices often involve operating ventilation systems at overestimated capacities, leading to energy inefficiency and environmental impact. Despite the existence of tools and solutions for mining ventilation, the incorporation of detailed 3D mapping for ventilation optimization remains notably absent in current practices.

Improvement of modern technology

The goals of the VOT3D project fit perfectly into the key objectives of the Raw Materials sector, aimed at safety increase, cost reduction, and sustainable production. The work included in the VOT3D project will improve the current technology and adapt it to harsh environments and expand the technology to TRL9 and access the global market and industry with versatile, innovative technology. Currently, there are many tools for mining ventilation modeling and analysis, as well as solutions aimed at ventilation optimization.

The VOT3D project aims to robotize the RM sector by introducing modern methods and innovative solutions for the optimization of underground ventilation with the main aim of reducing electricity consumption by 1,5%. VOT3D will try to get into a USD 326 million market with a CAGR of 4.3% during the forecast period from 2019-2024 and gain a 5% market share by exploiting emerging technologies to reduce costs (up to 2 mln € annually) for key mining operations and provide a safer working environment.

Key highlights of VOT3D concept

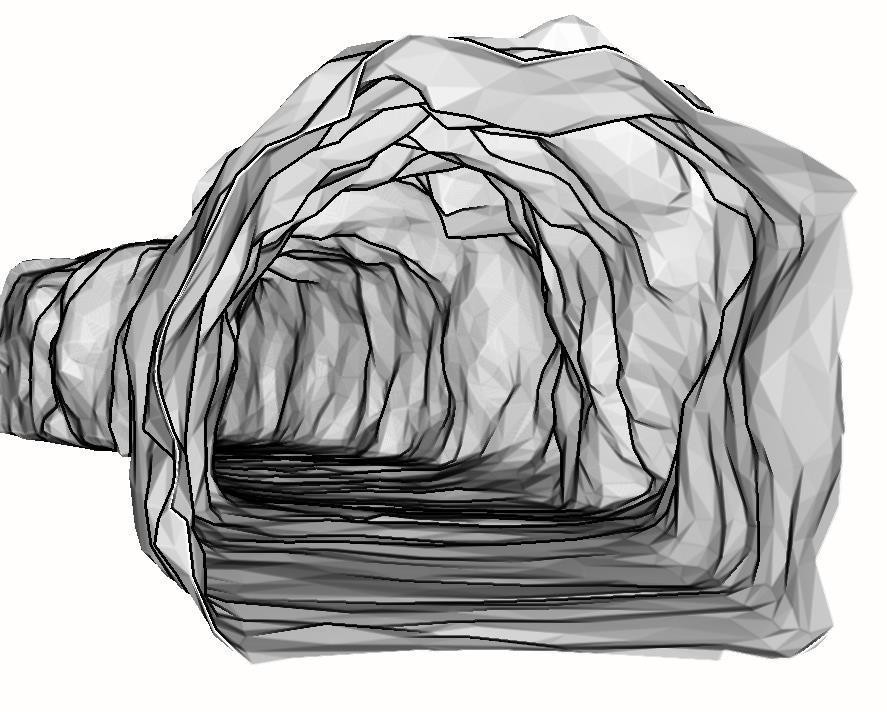

- UAV based system. Create a system based on a UAV platform capable of operating in underground mine conditions. By equipping the UAV platform with a special measurement system, based on laser scanning, the proposed solution will provide detailed 3D maps of mine workings.

- Computational modelling. VOT3D aims to utilise existing commercialised solutions for CFD modelling and ventilation calculations.

- Energy savings. Mine ventilation is a great consumer of power in underground mines, accounting for upward 40% of energy use. From the business perspective currently the main goal is to generate savings on energy costs while ensuring fresh, clean air for the crew in the workplaces.

- VOT3D project aims to optimize ventilation systems in underground mines targeting first potential buyers owing mines with complicated ventilation networks (e.g. deep mining facilities).

- Design precision. VOT3D upgrades the existing solution of ventilation design in by taking into consideration the real shape of the mine and its geospatial data.

Key contributions of VOT3D

- Securing raw materials supply: The project contributes to securing economically viable and sustainable raw materials supply in Europe by developing a new automated and digital technology that will enable enhancing mineral resources production efficiency.

- Responsible production: The solution developed under the VOT3D project is in line with the assumptions of sustainable development due to optimized airflow efficiency and thus reduction of energy consumption by 1,5%, providing operation of Strategic Materials and/or CRMs suppliers in a responsible way.

- Environmental sustainability: The reduced energy demand enables the mining companies to cut CO2 emissions immensely, since around 40% of a mine's energy requirements are needed for ventilation. This means that we can reduce CO2 emissions by around 12,000 tonnes per year. This supports the environmental and sustainability goals of the companies to actively support the achievement of climate targets.

- Safety enhancement: Through advanced technology, VOT3D minimizes human exposure to aerological hazards during data capturing, increasing the safety of underground crews, and aligning with modernization trends in the raw material industry.

VOT3D plays a pivotal role in achieving the aforementioned goals by upscaling innovative concepts to Technology Readiness Level (TRL) 9:

- Geometry measurement with scanning technologies.

- Mobile robotics (UAV).

- 3D data processing.

- Numerical modelling related to airflow, heat, pollution distribution in tunnels.

- Ventilation modelling software.